SOLUTIONS

Self-driving AI+Robotics Fast Development

OVERVIEW

AN INFINITY OF APPLICATIONS

The development process employs a self-driving artificial intelligence (A.I.) and high-throughput robotic experimentation workflow, which allows for an efficient search of the vast chemical and material space and zooming in on the possible subspace containing high-performance materials. This interdisciplinary approach will produce advanced materials for battery and broader material applications in a more efficient manner than the currently employed Edisonian processes.

STEP BY STEP

A SYSTEM DESIGNED FOR SOLUTIONS

KNOWLEDGE BASE

AI TRAINING

AI DOE PROPOSAL

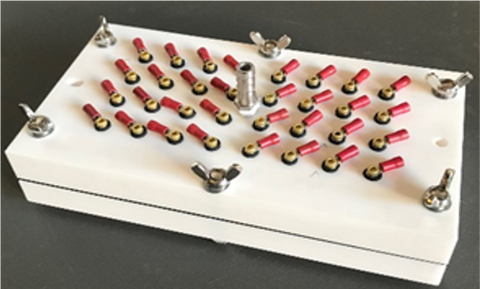

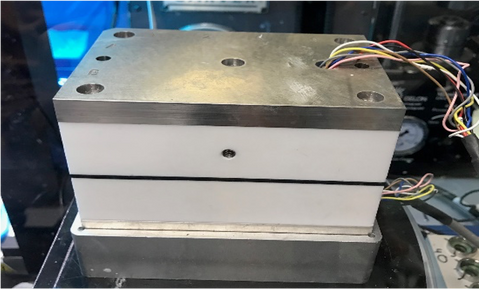

ROBOTIC EXPERIMENT

Golf Club/Facility:

Property enhancement

Polymer electrolyte is a key component in solid-state batteries that holds the promise of doubling the energy densities while halving the cost, with improved safety.

Our machine-learning prediction model learned from 960 reported electrolytes (consisting of 118 different chemicals in total) and their ionic conductivities. It is capable of accurately predicting the conductivity of a given new electrolyte (The Pearson correlation coefficient of LightGBM is 0.92)

Our machine-learning search model actively search for new electrolytes with higher ionic conductivity. Working together with our robotic high-throughput sample preparation and testing, many real electrolytes are discovered with conductivities orders of magnitude higher than the baseline electrolyte.

LITHIUM-METAL LIQUID ELECTROLYTE DEVELOPMENT

Automat Electrolyte

Conventional Electrolyte

The advancement of electric drive vehicle batteries is crucial for improving transportation energy efficiency. Batteries using high-capacity lithium metal anode hold promise due to their high energy densities to extend driving range and lower costs.

In this project, a novel class of high-energy-density batteries is developed by dropping lithium metal anode into conventional lithium-ion battery, enabled by an advanced liquid electrolyte.

A downselected electrolyte had stable full cell cycling in NCM111||coin cell configuration for 200 cycles and ongoing. In comparison, for a conventional electrolyte, the coulumbic efficiency did not reach 100%, and started to dip after 50 cycles. At cycle 96, the capacity fell below 80% of the initial capacity. The cell capacity retention was 45.0% at cycle 282.

BATTERY PERFORMANCE EARLY-CYCLE PREDICTION BY MACHINE LEARNING

To address lengthy battery cycle life testing (conventional 6+ months), the Automat team has developed a classification machine learning model to determine whether a cell battery sample will exhibit high or low performance based on early cycling data (<10 days). Several classification estimators were surveyed including, but not limited to, Gaussian Process Classification, Support Vector Classification, and Logistical Regression. All estimators were fitted using a Cross-Validation resampling technique to help mitigate any over-fitting with our limited number of data points. The machine learning classification model can achieve high prediction accuracy.